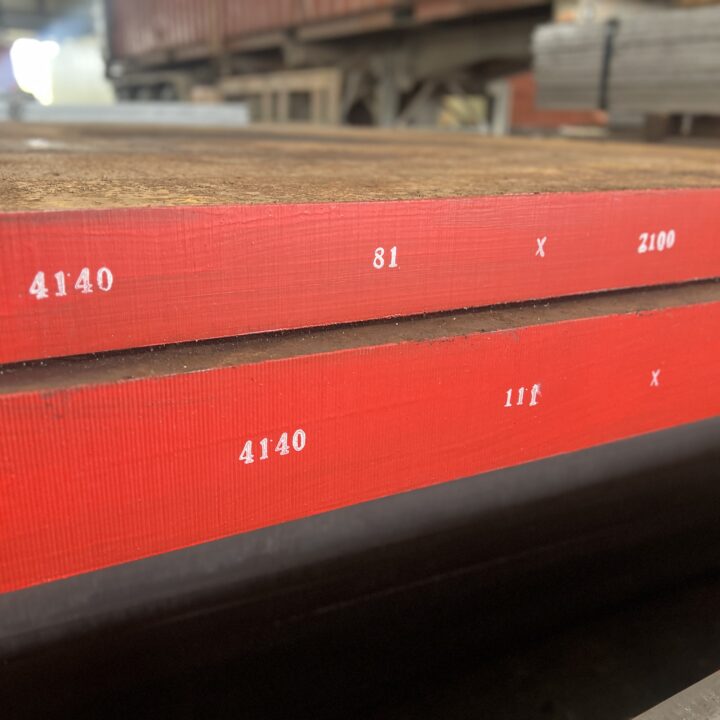

4140 steel is a low-alloy steels and mainly composition are chromium, molybdenum, and manganese and others

Composition and Properties

| C | Si | Mn | S | P | Cr | Mo | Ni | V | |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | ≤0.035 | 0.80-1.10 | 0.15-0.25 | / | / |

Heat Treatment

One of the important characteristics of 4140 steel is its adaptability to heat treatment. By adjusting it to specific heating and cooling processes, its hardness and toughness can fine-tuned to suit a wide range of applications.

Applications of 4140 alloy steel

4140 steel is widely used in various industries. It used to manufacture components in aerospace, automotive, oil and gas, construction and other fields. Its wide applicability makes it a prior choice material for engineers and factories.

Advantages of 4140 alloy steel

4140 steel offers a multitude of advantages that make it a preferred choice in various industries:

Exceptional Strength: With its high tensile strength and hardness after heat treatment, 4140 steel can withstand heavy loads and resist deformation.

Toughness: It has very good toughness, absorbing energy while not easily cracking or breaking, making it suitable for impact-resistant applications.

Versatility: The adaptability to heat treatment makes 4140 steel with a better of mechanical properties, making it suitable for diverse applications in a wide use situation.

Machinability: Unlike some other high-strength alloys, 4140 steel machine relatively easily, reducing production time and costs.

Cost-Effective: Considering its performance attributes, 4140 steel represents a cost-effective option for many applications.

Limitations and Considerations of 4140 alloy steel

While 4140 steel offers a host of advantages, it’s important to aware of its limitations:

While 4140 steel offers a host of advantages, it’s important to aware of its limitations:

Weldability Challenges: Although it can welded, it requires specific techniques and considerations, and may not be as straightforward as other materials.

Corrosion Resistance: While it does have some resistance, 4140 steel is not classified as a stainless steel and may require additional measures for highly corrosive environments.

Specific Heat Treatment Required: To fully harness its potential, 4140 steel must undergo precise heat treatment processes, which may not feasible for all applications.

In conclusion

In conclusion, 4140 alloy steel is an excellent material with a wide range of applications in various industries. Its combination of strength, toughness, workability and cost-effectiveness makes it the first choice of many engineers and factories. However, considering that some of its aspects require special conditions, such as heat treatment and welding technology requirements, it is crucial for 4140 alloy steel to realize its potential.

FAQs about 4140 alloy steel

Q1. How is 4140 steel typically used in the aerospace industry?

A1. In aerospace applications, 4140 steel is often utilized to manufacture components like landing gear, engine parts, and structural elements due to its high strength-to-weight ratio.

Q2. Can 4140 steel be used in corrosive environments without additional treatment?

A2. While it does have some corrosion resistance, for highly corrosive environments, additional protective coatings or treatments may be necessary.

Q3. What is the process of heat treating 4140 steel?

Q3. What is the process of heat treating 4140 steel?

A3. Heat treating 4140 steel involves heating it to a specific temperature, holding it at that temperature, and then cooling it at a controlled rate to achieve the desired mechanical properties.

Q4. Are there alternatives to 4140 steel for applications requiring high strength and toughness?

A4. Yes, there are other high-strength alloys that can replace 4140 steel under certain conditions, such as 4340 steel, which we have mentioned in previous articles.

Please consult the professional engineer or manufacturer to select a proper materials if you requested used in a special occasions or conditions . If you would like to know whether the 4140 is suitable for your needs, please feel free to ask us.

Or you can visit our main website: http://www.otaisteel.com

Contact: Joann E-mail:+8613128068365 WhatsApp:+8613128068365