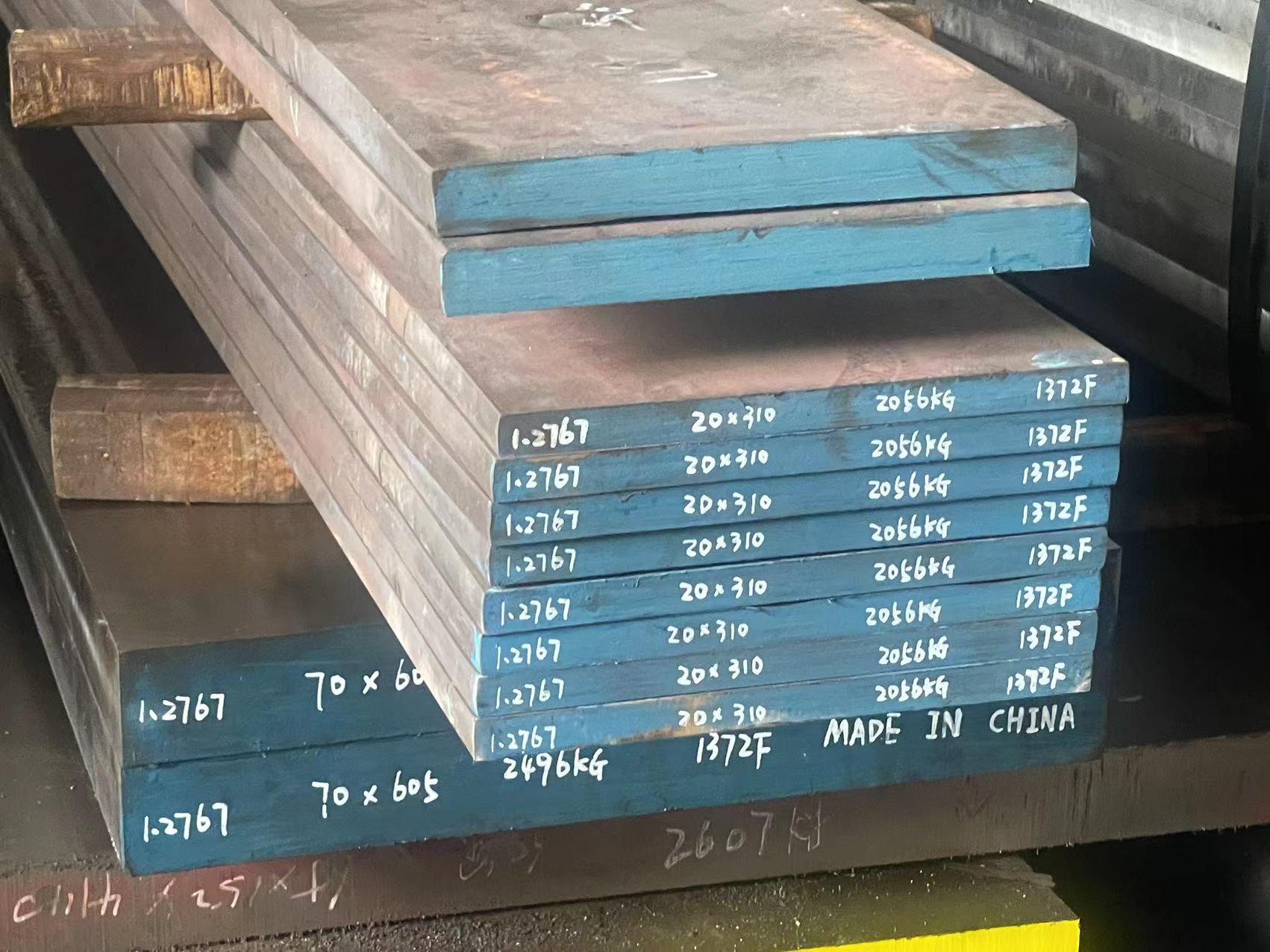

1.2767 also known as 45NiCrMo16, belongs to BS EN ISO 4957 standard cold work tool steel. This steel has high wear resistance and toughness, and good hardenability. Suitable for heavy-duty imprinting molds, forming molds, heavy-duty cold work tools, shearing tools, etc. In this post, we will delve into the intricacies of 1.2767 steel, exploring its characteristics, applications, and why it stands out among its counterparts.

Unveiling the Composition of 1.2767 Steel

At the heart of 1.2767 lies a carefully crafted composition that imparts unique qualities to this alloy.

The special chemical composition caurse it hardness max 285HB after annealed, it higher than other tool steels.

| Grade | C | Si | Mn | S | P | Cr | Mo | Ni |

| 1.2767 | 0.40-0.50 | 0.10-0.40 | 0.20-0.50 | ≤0.030 | ≤0.030 | 1.20-1.50 | 0.15-0.35 | 3.80-4.30 |

The Robust Nature of 1.2767 Steel: Toughness Redefined

Toughness is a crucial aspect of any steel alloy, and 1.2767 takes it a step further. The inherent toughness of this alloy makes it particularly well-suited for applications that require resistance to impact and heavy loads. Industries ranging from manufacturing to construction have embraced 1.2767 for its ability to withstand challenging environments, ensuring longevity and reliability in performance.

Applications

Applications

The versatility of 1.2767 extends to its wide array of applications across diverse industries. In the realm of tool and die making, this steel variant is a popular choice for its ability to maintain its hardness even at elevated temperatures. Additionally, industries involved in the production of heavy-duty components, such as punches, dies, and forming tools, have found a reliable ally in 1.2767 steel.

Machinability Matters: 1.2767 Steel in the Workshop

Efficiency in machining is a priority for manufacturers, and 1.2767 doesn’t disappoint. The alloy exhibits commendable machinability, allowing for intricate designs and precise tooling. This quality makes it a favorite in workshops where precision is paramount, contributing to the seamless production of components across various sectors.

Unlocking the Heat Treatment Potential

One of the standout features of 1.2767 is its response to heat treatment. The alloy can be subjected to different heat treatment processes, including annealing and quenching, to enhance specific properties. This adaptability makes it a versatile choice for applications where tailored material characteristics are essential for optimal performance.

1.2767 Steel in the Modern Industrial Landscape: Meeting Standards and Beyond

As industries evolve, so do the standards that govern them. 1.2767 aligns with and often exceeds industry standards, ensuring that it meets the stringent requirements of modern applications. Whether in the automotive sector, aerospace industry, or general manufacturing, this steel variant continues to prove its mettle, consistently outperforming expectations.

Navigating the Corrosion Resistance: A Key Advantage

Corrosion can be a silent adversary, gradually eroding the integrity of materials. In the case of 1.2767 , its inherent corrosion resistance adds a layer of durability. This quality extends the lifespan of components made from this alloy, making it a reliable choice for outdoor applications and environments prone to moisture and other corrosive elements.

The Economic Edge: Long-Term Viability of 1.2767 Steel

Beyond its technical attributes, 1.2767 offers an economic advantage to industries. The longevity of components made from this alloy translates to reduced maintenance costs and increased operational efficiency. As businesses seek sustainable solutions, the long-term viability of 1.2767 steel positions it as a strategic choice for those looking to optimize both performance and cost-effectiveness.

Conclusion: Embracing the Strength of 1.2767 Steel

In conclusion, 1.2767 emerges as a stalwart in the world of steel alloys, showcasing a balance of toughness, machinability, and corrosion resistance. Its applications span across industries, contributing to the seamless functioning of machinery and tools in diverse settings. As we navigate the dynamic landscape of materials engineering, 1.2767 stands tall as a reliable companion, ready to face the challenges of the modern industrial era.

Frequently Asked Questions (FAQs)

1. Can 1.2767 steel be used for high-precision components?

Yes, the machinability of 1.2767 makes it suitable for high-precision components, meeting the stringent requirements of industries where precision is paramount.

2. How does 1.2767 steel compare to other tool steels in terms of toughness?

1.2767 exhibits excellent toughness, making it comparable and often superior to other tool steels, especially in applications requiring resistance to impact and heavy loads.

3. What is the recommended heat treatment process for 1.2767 steel?

The heat treatment process for 1.2767 can vary based on the desired properties, but commonly includes annealing and quenching to achieve the optimal balance of hardness and toughness.

4. Is 1.2767 steel cost-effective in the long run for industrial applications?

Yes, the economic edge of 1.2767 lies in its long-term viability, contributing to reduced maintenance costs and increased operational efficiency, making it a cost-effective choice for industries.

5. Can 1.2767 steel be used in outdoor applications prone to corrosion?

Certainly, the corrosion resistance of 1.2767 makes it suitable for outdoor applications where exposure to moisture and other corrosive elements is a concern.

Want to know more about the details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365