1.2316 (X38CrMo16) steel is a prehardened mold steel recognized for its superior corrosion resistance, achieved through the addition of chromium and molybdenum. It widely apply in mold applications, including cores, inserts, and mold cavities, this steel also use for the production of corrosive materials like PVC.

Standard:

DIN 1.2316 steel belongs to the DIN standard EN ISO 4957 :2018

1.2316 Steel Equivalent and Chemical Composition

1.2316 Steel Equivalent and Chemical Composition

| Standard | Steel Grade | |||||||

| Chemical composition % | ||||||||

| C: | Mn: | Si: | P: | S: | Cr: | Mo: | Ni: | |

| EN 10088-3:2014 | X39CrMo17-1 – 1.4122 | |||||||

| 0.33 – 0.45 | <1.5 | <1.0 | <0.04 | <0.03 | 15.5 – 17.5 | 0.8 – 1.3 | <1.0 | |

| ISO 4957:2018 | X38CrMo16 – 1.2316 | |||||||

| 0.33 – 0.45 | <1.5 | <1.0 | <0.03 | <0.03 | 15.5 – 17.5 | 0.8 – 1.3 | <1.0 | |

| DIN 17350:1980 | X36CrMo17 – 1.2316 | |||||||

| 0.33 – 0.43 | <1.0 | <1.0 | <0.03 | <0.030 | 15.0 – 17.0 | 1.0 – 1.3 | <1.0 | |

| NF A35-590 | Z38CD16-01 | |||||||

| 0.33 – 0.45 | <1.0 | <1.0 | <0.04 | <0.015 | 15.5 – 17.5 | 0.8 – 1.3 | – | |

| NF | Z35CD17 | |||||||

| 0.33 – 0.45 | <1.5 | <1.0 | <0.03 | <0.03 | 15.5 – 17.5 | 0.8 – 1.3 | <1.0 | |

| PN | 3H17M | |||||||

| 0.33 – 0.43 | <1.0 | <1.0 | <0.045 | <0.030 | 15.5 – 17.5 | 1.0 – 1.3 | <1.0 | |

1.2316 Steel Physical Properties:

| Thermal conductivity W.m-1.K-1 | Thermal expansion Coefficient (10-6.K-1) | ||||

| 20°C | 20-100°C | 20-200°C | 20-300°C | 20-400°C | Specificheat J/kg.°C |

| 24.3 | 11 | 11.1 | 11.4 | 11.7 | 460 |

1.2316 Steel Mechanical Properties:

1.2316 delivery condition usually quenched and tempered to 280 – 325 HB (29 – 33 HRC)

| Hardness | Rp 0.2 Yield Strength |

Rm Tensile strength |

Elongation | Reduction of area | Elastic modulus | |||

| HB | MPa | ksi | MPa | ksi | % | Z% | GPa | ksi |

| 300 | 855 | 124 | 1020 | 148 | 13 | 38 | 205 | 29733 |

DIN 1.2316(X38CrMo16) steeel Heat treatment:

1.2316 steel l is normally supplied in the quenched and tempered condition with a hardness of approximately 300 HB.

1.2316 steel l is normally supplied in the quenched and tempered condition with a hardness of approximately 300 HB.

- Annealing: 760 to 800 °C for about 4 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 650 °C; further cooling in air, max. 230 HB

- Stress Relieving: Soaking is done at temperature 600 – 650°C and then it is furnace cooled. This process is done at approx. 650 °C.

- Hardening: Heat to 1020 – 1040 °C. Quench in oil at 500 – 550°C. Hardness after quenching: 48 – 52 HRC

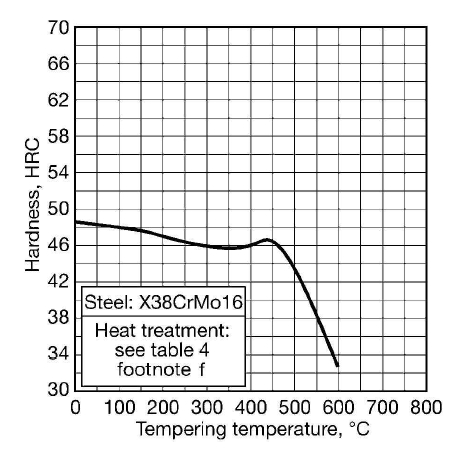

- Tempering: The hardness varies depending on the tempering temperature, ranging from 32 HRC to 49 HRC.

In case of complicated parts, holding time should be determined considering the thicker section of the part.

1.2316 Steel Applications:

-Suitable for manufacturing PVC, POM and other plastic products, or other corrosive plastics and high-gloss plastic molds;

-Thermoplastic plastic injection molds, extrusion molds;

-Thermoplastic blow molds;

-Main components of heavy-duty mold;

-Cold structural parts;

-It often use in the manufacture of TV casings, washing machines, refrigerator inner casings, buckets, etc.

Quality Assurance and Certification:

– Ensuring that the steel aligns with industry standards is crucial. Verify relevant certifications, such as DIN EN ISO 9001 for quality management systems.

Considerations for Buyers:

– Stress the importance of understanding the application’s specific requirements to choose the most suitable steel grade.

– Provide MTCs to check the chemical compositions and propertities if it is meet the material requirement

Conclusion:

1.2316 steel is a versatile mold steel offering prehardened convenience, excellent corrosion resistance, and adaptability to humid environments. Thanks to its mechanical and physical properties and coupled with straightforward heat treatment, make it a preferred choice for various applications in the mold industry.

Want to know more about the details of 1.2316, stock list and price , pls contact :

E-mail:joann@otaisteel.com

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365