DIN 1.2436 is German DIN standard extra high toughness chromium steel and cold work mould steel. Has extremely high wear resistance and edge retention capabilities. It is a widely used cold work die steel with high strength, good hardenability and good wear resistance, but the weak point is it poor impact toughness. 1.2436 adds 0.6%-0.8% tungsten compare with 1.2080, so its wear resistance is better than 1.2080 steel. However, compared with 1.2379, because a certain amount of vanadium is added to 1.2379 steel , it toughness performace better than 1.2436. Therefore, 1.2436 s mainly used for cold stamping dies and punches, cold cutting shears, drill bushings, and gauges that bear smaller impact loads and require high wear resistance , drawing dies, impression dies, thread rolling dies, drawing dies and thread rolling dies, etc.

Standard:

DIN 1.2436 belong to German Industrial Standard (DIN) DIN EN ISO 4957 .

Chemical Composition and Equivalent Steel:

| DIN ISO 4957 | C | Mn | P | S | Si | Cr | W | |||||

| 1.2436 / X210CrW12 | 2.00 | 2.30 | 0.30 | 0.60 | 0.03 | 0.03 | 0.10 | 0.40 | 11.00 | 13.00 | 0.60 | 0.80 |

| JIS G4404 | C | Mn | P | S | Si | Cr | W | |||||

| SKD2 | 2.00 | 2.30 | 0.30 | 0.60 | 0.03 | 0.03 | 0.10 | 0.60 | 11.00 | 13.00 | 0.60 | 0.80 |

| ASTM A681 | C | Mn | P | S | Si | Cr | W | |||||

| D6 | 2.00 | 2.20 | 0.20 | 0.40 | 0.03 | 0.03 | 0.20 | 0.40 | 11.50 | 12.50 | 0.60 | 0.90 |

DIN 1.2436 Physical Properties:

DIN 1.2436 Physical Properties:

1. Density: 7.80 g/cm³.

2. Melting Point: A scorching 1426°C (2599°F).

3. Thermal Conductivity: Playing it cool with 24 W/(m·K).

4. Specific Heat: Holding its heat with 0.46 J/g·K.

5. Electrical Resistivity: A light touch at 0.40 µΩ·m.

6. Coefficient of Thermal Expansion: A modest 10.5 x 10^-6/°C (20-100°C).

DIN 1.2436 Mechanical Properties:

1. Hardness (Annealed): Max 255 HB (Brinell Hardness).

2. Tensile Strength: A robust 700-800 MPa.

3. Yield Strength: A sturdy 600 MPa.

4. Elongation at Break: A flexible 14%.

5. Reduction in Area: A resilient 45%.

6. Modulus of Elasticity: A firm handshake at 210 GPa.

Applications:

1. Crafting Cold Work Tools: DIN 1.2436 steel takes the lead in creating the backbone of cold work tools—forming dies, blanking, and shearing tools.

2. Mastering Precision Machining:Its rock-hard nature and resistance to wear make it the maestro in precision and accuracy-demanding applications.

3. Tooling the Cutting Edge: Employed in the crafting of cutting tools for diverse materials, thanks to its durability.

4. Stamping and Embossing Star: Industries with an eye for tight tolerances revel in the precision offered by this tool steel.

5. Blades of Industry: Takes center stage in the fabrication of industrial blades for various cutting applications.

Heat Treatment :

Temperature |

Cooling |

Hardness |

|

Soft annealing |

800 – 840 °C |

Furnace |

250 HB |

Stress Relief Annealing |

600 – 650°C |

Furnace |

|

Hardening |

960 – 980°C |

oil, pressure gas (N2), air or hot bath 500 – 550°C |

See Tempering Diagram |

FAQs about 1.2436 Steel

FAQs about 1.2436 Steel

Q1: What industries commonly use DIN 1.2436?

DIN 1.2436 finds its rhythm in industries such as cold Work Tools ,cutting and drill, thanks to its versatile properties.

Q2: Can DIN 1.2436 heat things up in high-temperature applications?

While DIN 1.2436 dances elegantly in cold work applications, it might not be the star performer in high-temperature scenarios. 1.2379 steel properties might take the spotlight.

Q3: How does the heat treatment effect the DIN 1.2436’s performance?

The heat treatment ballet elevates the hardness and toughness of DIN 1.2436, letting manufacturers choreograph its properties based on specific application needs.

Q4: Is DIN 1.2436 a cost-effective partner in the long run?

Absolutely! The lasting power and wear resistance of tools born from DIN 1.2436 contribute to a cost-effective symphony over time, reducing the need for constant replacements.

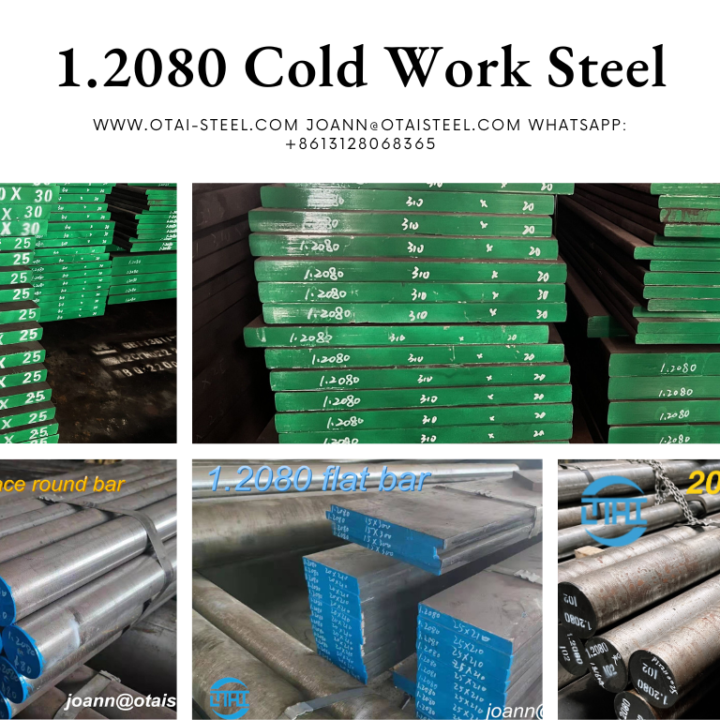

Want to know more about the D6/1.2436 ( X210CrW12 ) /SKD2 steel details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365