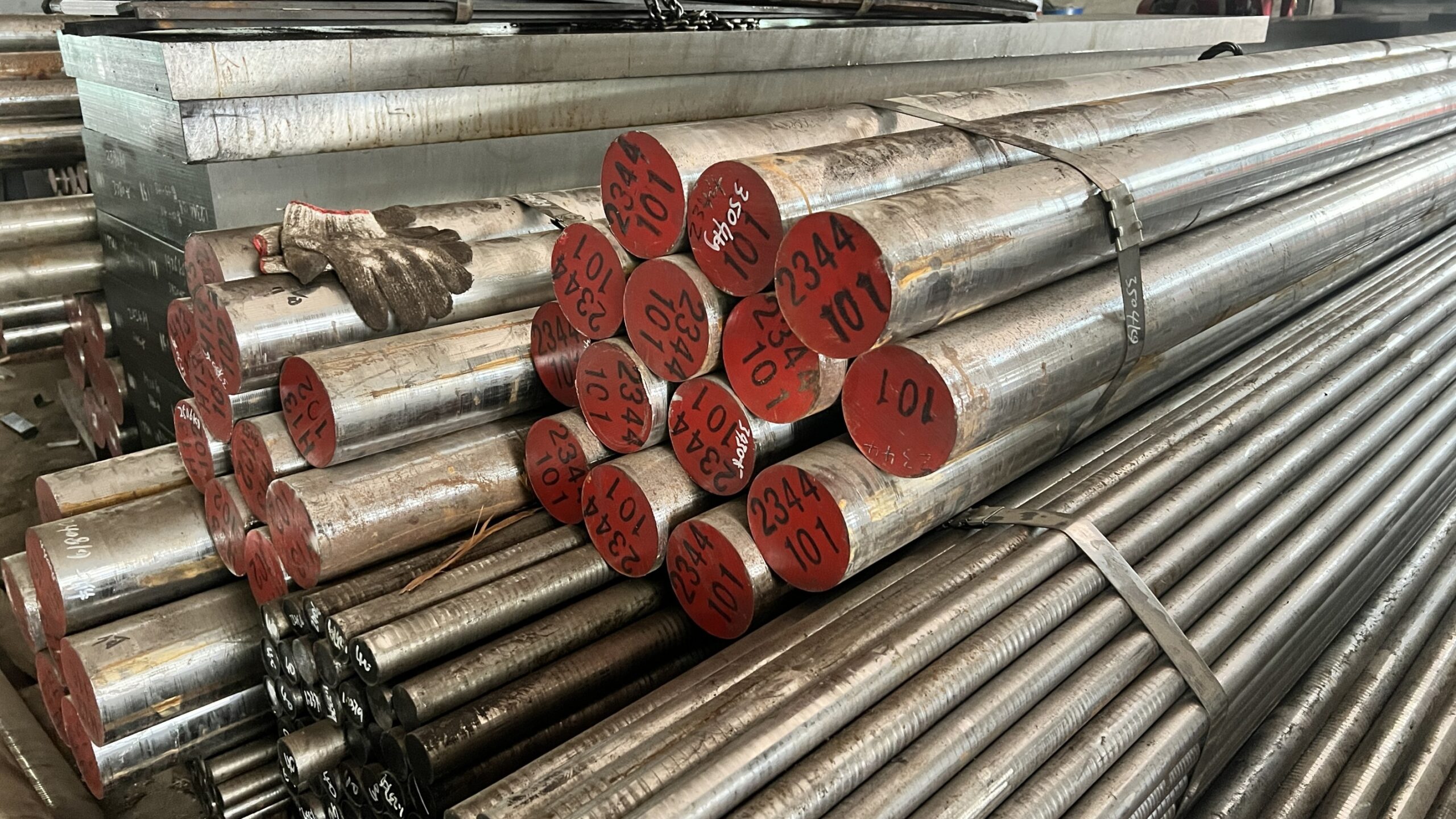

Steel is the backbone of many industries, and within this robust material family, 1.2344 steel stands out for its exceptional properties and versatile applications. In this guide, we’ll delve into the details of 1.2344 steel, exploring its composition, characteristics, applications, and much more.

What is 1.2344 Steel?

1.2344 steel, also known as H13 tool steel, belongs to the family of chromium hot-work steels. Its composition making it a high-performance steel variant.

Composition and Properties of 1.2344 steel

| C | Si | Mn | S | P | Cr | Mo | Ni | V | ||

| 1.2344 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | ≤0.030 | ≤0.030 | 4.80-5.20 | 1.20-1.50 | / | 0.85-1.15 |

The alloying elements in 1.2344 contribute to its unique set of properties. Chromium enhances wear resistance, molybdenum improves strength at elevated temperatures, and vanadium refines grain structure, enhancing toughness.

High Hardness and Wear Resistance

1.2344 steel is renowned for its high hardness, making it suitable for applications where wear resistance is crucial. This property is vital in industries like metal forming and extrusion.

Excellent Toughness at High Temperatures

Excellent Toughness at High Temperatures

One of the standout features of 1.2344 is its excellent toughness even at high temperatures. This makes it ideal for hot-work applications such as die casting and forging.

Good Heat Conductivity

The steel’s good heat conductivity ensures uniform heat distribution during processing, contributing to its reliability in various manufacturing processes.

Applications of 1.2344 steel

Die Casting and Forging

1.2344’s exceptional toughness and high-temperature resistance make it a preferred choice for die casting and forging applications. It ensures durability and longevity in the demanding conditions of these processes.

Extrusion and Metal Forming

In industries where metal deformation is a common practice, 1.2344 shines. Its wear resistance and hardness make it a reliable material for extrusion and metal forming dies.

Tooling and Molds

Tooling and Molds

Tool and mold industries benefit significantly from the properties of 1.2344 steel. Its versatility allows for the creation of robust and durable tools and molds, ensuring precision in various manufacturing processes.

Structural Components in Aerospace

Given its high strength and toughness, 1.2344 finds applications in the aerospace industry, particularly in the production of structural components subjected to extreme conditions.

Advantages

1. Versatility: Its adaptability to various manufacturing processes makes it a versatile choice in multiple industries.

2. Durability: The high hardness and wear resistance contribute to the longevity of tools and components made from 1.2344 .

3. Precision: In tooling and mold applications, the steel’s properties ensure precision in the manufacturing of intricate components.

4. High-Temperature Performance: Industries requiring materials to withstand high temperatures, such as die casting and forging, benefit from 1.2344’s exceptional performance.

Conclusion

In conclusion, 1.2344 steel stands as a stalwart in the realm of high-performance steels. Its composition, properties, and diverse applications make it a crucial player in industries ranging from metal forming to aerospace. The balance of hardness, toughness, and heat resistance positions it as a reliable choice for the most demanding applications.

FAQs

FAQs

Q1: Can 1.2344 be used in high-precision applications?

A1: Yes, 1.2344 steel’s high hardness and wear resistance make it suitable for high-precision tooling and mold applications.

Q2: How does 1.2344 compare to other hot-work steels?

A2: Compared to other hot-work steels, 1.2344 steel offers a unique combination of high hardness, excellent toughness, and good heat conductivity.

Q3: What industries commonly use 1.2344 ?

A3: 1.2344 steel finds applications in die casting, forging, extrusion, metal forming, tooling, molds, and aerospace industries.

Q4: Is there a specific heat treatment process for 1.2344 ?

A4: Yes, 1.2344 steel undergoes a precise heat treatment process to optimize its mechanical properties for different applications.

Q5: Can 1.2344 withstand extreme temperatures in aerospace applications?

A5: Absolutely, the high-temperature performance of 1.2344 steel makes it a reliable choice for structural components in aerospace subjected to extreme conditions.

Want to know more about the details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365