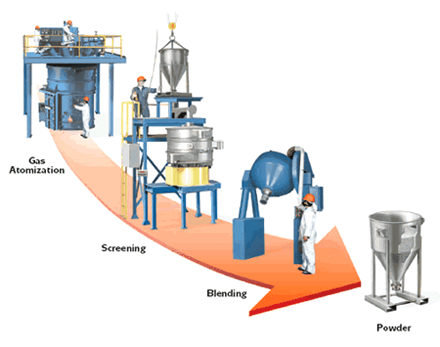

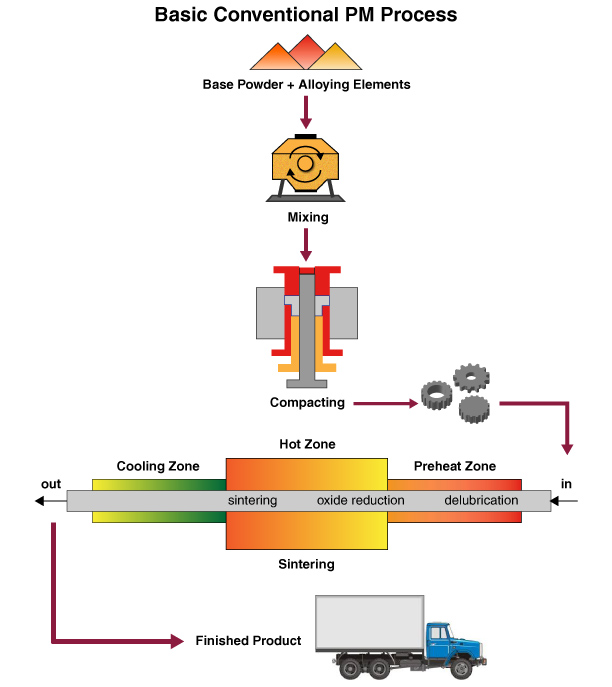

Before understanding powder high-speed steel, we first understand what powder metallurgy is. Powder metallurgy refers to a steel manufacturing process in which fine steel powder is obtained by atomizing molten steel with high-pressure inert gas or high-pressure water, then pressed into shape under high temperature and high pressure, and then sintered. Powder metallurgy high-speed steel also call PMHSS which is high-speed steel manufactured through powder metallurgy process.

Manufacturing process of Powder metallurgy high speed(PMHSS)

-

- Atomized high-speed steel: First, pour the high-speed steel into high-pressure inert gas or high-pressure water to atomize it into fine high-speed steel powder.

- Press molding:Put the high-speed steel powder obtained after atomization into a mold and press it into shape under high temperature and high pressure.

- Sintering: Put the pressed blank into a sintering furnace and perform sintering treatment to make it completely densified.

- Heat treatment: Finally, the sintered blank make heat treatment to adjust its structure and properties.

- Atomized high-speed steel: First, pour the high-speed steel into high-pressure inert gas or high-pressure water to atomize it into fine high-speed steel powder.

The difference between Powder metallurgy high speed(PMHSS)and traditional HSS

Wear resistance

Since the particles (powder) of PMHSS are small and uniform, there will be no uneven solidification, and the internal structure is uniform and stable. Therefore, under the same heat treatment and quenching temperature, the wear resistance of PMHSS will be better than ordinary HSS.

Purity

Before PMHSS is prepared and formed, its raw materials (powder) will be strictly filtered and screened. This will completely remove impurities and non-metallic substances from the raw material. At the same time, the composition of PMHSS is stabilized after molding to ensure product quality.

No directionality

Powder metallurgy high-speed steel(PMHSS) is made of extremely small particles (powder) that are pressed and sintered, so the performance and strength of all parts of the entire product will be the same. There will be no horizontal or vertical organizational structure like ordinary high-speed steel. Therefore, the overall performance of the entire product also be higher.

Regular deformation

Although powdered high-speed steel has a special structure, dimensional deformation will also occur during the heat treatment process. However, compared with the irregular deformation of ordinary high-speed steel, PMHSS will cause regular deformation of the entire product. In other words, during the heat treatment process of grinding high-speed steel, all parts will become larger at the same time.

Difference in price

The production process of powder metallurgy high-speed steel is complex and the cost is high.

PMHSS is generally 4 to 8 times more expensive than ordinary high-speed steel, so it is usually used to manufacture precision and complex tools or tools for CNC machine tools.

However, the performance of cutting tools made of PMHSS is better than that of ordinary HSS, and the service life is longer than that of ordinary HSS (generally 2 to 3 times).

Application of Powder metallurgy high speed (PMHSS)

- Powder metallurgy high speed steel has good mechanical properties. Suitable for manufacturing: tools that are prone to chipping under intermittent cutting conditions, tools with high strength and sharp cutting edges. Such as gear shaper cutters, hobs, milling cutters, and tools used under high-pressure dynamic loads.

- It has small carbide segregation, fine grains and good wear resistance. Suitable for manufacturing: large-size knives, precision knives, complex knives.

- This type of material has high thermal hardness at high temperatures and is suitable for making tools for difficult-to-machine materials. It is indeed comprehensive.

The development of Powder metallurgy high speed in China

Although China is a major producer of high-speed steel cutting tools, with output and export volume ranking first in the world, China’s high-speed steel industry is still limited by technical barriers and other factors. Currently, the high-end high-speed steel market is still monopolized by overseas brands. At present, most of the powdered metallurgy high-speed steel (PMHSS) is still imported into China.

Due to the high price, many users cannot afford the high cost. In recent years, China has also begun to develop Chinese powder high-speed steel, such as TG’s TPM330. The following is a comparison of the chemical composition of TPM330 with ASP23 and M3-2

| C | Cr | Mo | V | W | Si | Mn | S | P | |

| M3-2 | 1.15-1.25 | 3.75-4.50 | 4.75-6.50 | 2.75-3.25 | 5.00-6.75 | 0.20-0.45 | 0.15-0.40 | Max 0.030 | Max 0.030 |

| ASP23 | 1.28 | 4.20 | 5.00 | 3.10 | 6.40 | ||||

| TPM330 | 1.28 | 4.10 | 5.00 | 3.00 | 6.40 |

Although China’s TPM330 cannot completely replace ASP23 at present, it is undoubtedly the most cost-effective choice. Under the use conditions of some punch materials, the national standard TPM330 also has a longer service life and better performance than ordinary ones such as M2, M42, and DC53. However, for IC packaging molds and complex-shaped workpieces, you can only choose ASP23 because the purity cannot reach TG. TG is the third generation of powder metallurgy, and ASP is the fifth generation.

In conclusion

The special and advanced smelting method of PMHSS is an innovation in high-speed steel smelting, which creates a new steel type with properties between cemented carbide and ordinary HSS. The rise of PMHSS has brought new breakthroughs in tool materials for the machinery manufacturing and processing industry. As a new steel type with excellent performance, it has gradually been recognized, accepted and loved by people, and is playing an increasingly important role in the machinery industry.

In short, PMHSS is a very excellent high-performance steel with fine grain structure, high wear resistance, high toughness and other characteristics. And is suitable for high-precision and high-efficiency processing applications.

It can be used not only to manufacture various types of tools and cutters, but also to manufacture high-quality mechanical parts and bearings, etc. In the future, with the continuous development of powder metallurgy technology, it is believed that the application scope of PMHSS will be further expanded.

Currently , Otai stock PMHSS TPM330 flat bar size

150*200/ 150*300 /200*200 /200*300

If you want to know more about the PMHSS information and the TPM330 stock , please contact