Cr12MoV steel is a kind of high carbon and high chromium steel, it is belong to GB/T 1999-2000. Typical steel types such as Cr12, Cr12MoV, Cr12Mo1V1, D2, SKD11,X12MF etc. Cr12MoV have a carbon content of over 1.40% and a chromium content of 11.00%~13.00% and has excellent properties such as hardenability, hardness and flexural strength. It is an important material for manufacturing stamping dies, cold forming dies and other molds. It is widely used in various curved parts and molds with large cross-sections and complex shapes.

Chemical Compostion and it’s equivalent Grade:

| Steel | Country Code | C(%) | V(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) |

| D2 | ASTM | 1.40-1.60 | 0.50-1.10 | 0.10-0.60 | 0.10-0.60 | ≦0.030 | ≦0.030 | 11.0-13.0 |

| Cr12MoV | GB | 1.45-1.70 | 0.15-0.30 | ≦0.40 | ≦0.40 | ≦0.030 | ≦0.030 | 11.0-12.5 |

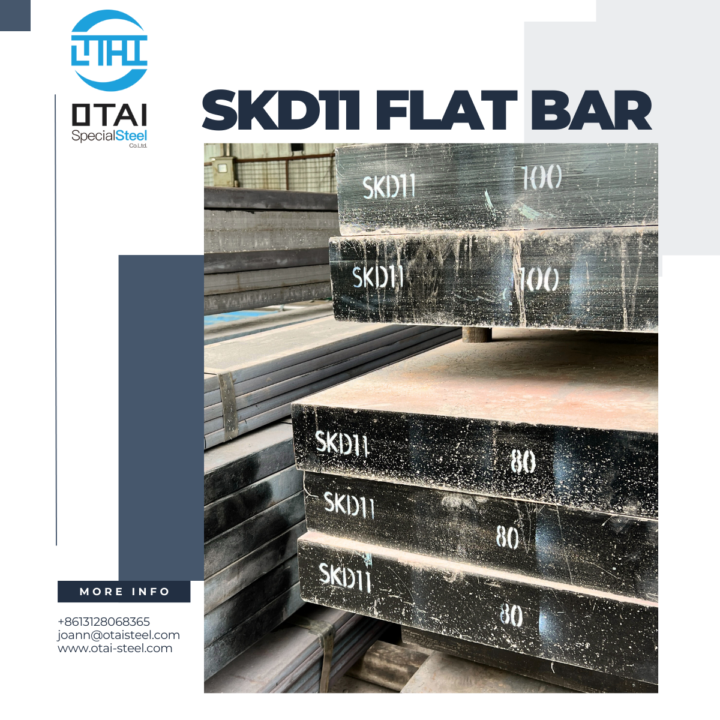

| SKD11 | JIS | 1.40-1.60 | 0.20-0.50 | ≦0.40 | ≦0.60 | ≦0.030 | ≦0.030 | 11.0-13.0 |

| X165Cr-MoV12 | DIN | 1.55-1.75 | 0.10-0.50 | 0.25-0.40 | 0.2-0.4 | ≦0.030 | ≦0.030 | 11.0-12.0 |

CR12MOV steel has improved the hardenability and hardenability of the steel due to the addition of appropriate amounts of chromium, molybdenum, vanadium and other alloying elements, making the material’s comprehensive mechanical properties after quenching much higher than other types of steel, and is widely used in the manufacture of molds.

Cr12MoV Steel Heat Treatment

Annealing

Annealing

800 to 850°C

Slow controlled cooling in furnace at a rate of 10 to 20°C/hr down to approx. 600°C, further cooling in air. Hardness after annealing: max. 250 HB.

Stress relieving

650 to 700°C

Slow cooling in furnace; intended to relieve stresses set up by extensive machining, or in complex shapes. After through heating, hold in neutral atmosphere for 1-2 hours.

Hardening

980 to 1010°C

Oil, salt bath (220 to 250°C or 500 to 550°C), air blast, still air. Tools of intricate shape or with sharp edges should preferably be hardened in air or salt bath. Holding time after temperature equalization: 15 to 30 minutes.

Obtainable hardness: 63 – 65 HRC

Tempering

Slow heating to tempering temperature immediately after hardening/time in furnace 1 hour for each 20 mm of workpiece thickness but at least 2 hours/cooling in air.

For certain cases we recommend to reduce tempering temperature and increase holding time

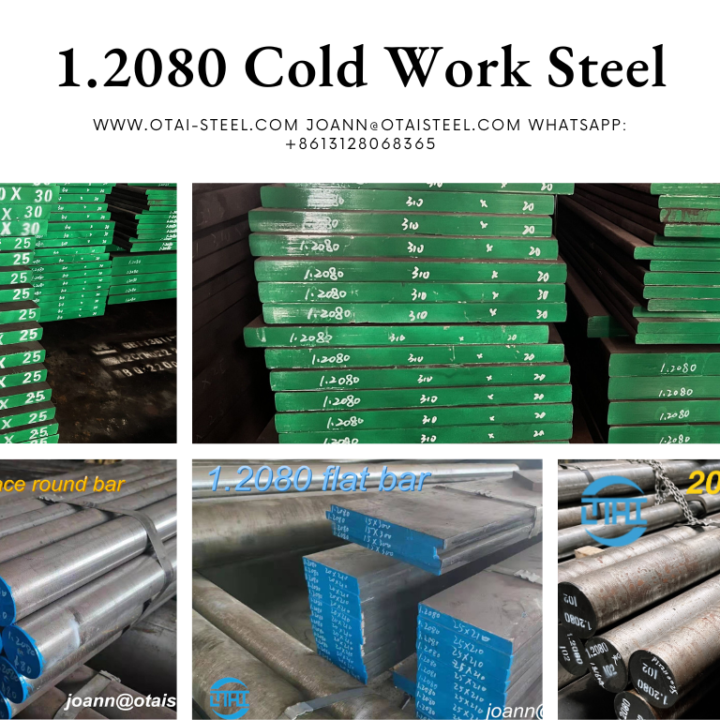

Cr12MoV Steel Delivery Condition:

Annealed , 207-255HB

Cr12MoV Steel Application:

Cold work dies

- Cr12MoV steel is widely used in the manufacture of cold work dies with large cross-sections, complex shapes, large impact forces, and high wear resistance requirements, such as silicon steel sheet punching dies, cold cutting scissors, trimming dies, thread rolling dies, wire drawing dies, rolling dies, etc. Wire plate, thread rolling die, complex-shaped punching die, steel plate drawing die, etc.

- The service life of the rolls used to replace Cr2 steel in manufacturing rolled and welded steel pipes is increased by more than 7 times.

Extrusion punches

- For pure aluminum blank reverse extrusion punches made of this steel, when the pressure is about 1000MPa, the life of the punch is guaranteed to be more than 50,000 pieces. The main failure modes are wear and surface roughening.

- Used to manufacture punching dies with material thickness >3mm, punch dies, concave dies, and inserts with complex shapes. The recommended hardness is 58-62HRC when making punch molds, and the recommended hardness is 60-64HRC when making concave molds.

- Used to make punches and concave dies that require high wear resistance in punching dies. When making punches, the recommended hardness is 60-62HRC, and when making concave dies, the recommended hardness is 62-64HRC.

- Used to manufacture concave dies that require high wear resistance in drawing dies. The recommended hardness is 62-64HRC.

- Used to manufacture punches, concave dies, and inserts that require high hardness and complex shapes in bending dies. The recommended hardness is 60-62HRC when making punches, and 60-64HRC when making concave dies.

- Used to make cold extrusion dies for aluminum parts. The recommended hardness for making punch molds is 60-62HRC, and for making concave molds, the recommended hardness is 62-64HRC.

- Used to manufacture cold extrusion concave and convex molds for copper parts. The recommended hardness is 62-64HRC.

Bend spring steel plates

- Used to bend spring steel plates with a carbon content of 0.65%-0.80% (mass fraction), a hardness of 37-42HRC, and a service life of up to 150,000 times. If nitriding treatment carry out, the service life can reach 400,000 times.

- When used to manufacture thread rolling dies for processing 20Mn steel, after repeated upsetting and elongation, the carbide unevenness of the blank is ≤3, then the service life of the thread rolling dies will be increased from the original 20,000 pieces to 500,000 pieces.

Plastic molds

- Used for manufacturing thermosetting plastic forming molds and general plastic molds.

- Cr12MoV steel stainless steel mold vacuum quenching + gas nitriding. At present, most domestic stainless steel molds are made of Cr12MoV steel.

Want to know more about the Cr12MoV steel details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365