Composition and Properties:

Both 4340 and 4140 steels belong to the alloy steel category and are composed of similar elements. The main composition of steel are iron, carbon, chromium, molybdenum and manganese. The difference between different steel types mainly based on the content of chemical compositions.

| C | Si | Mn | S | P | Cr | Mo | Ni | |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | ≤0.035 | 0.80-1.10 | 0.15-0.25 | |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.60-0.80 | ≤0.040 | ≤0.035 | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 |

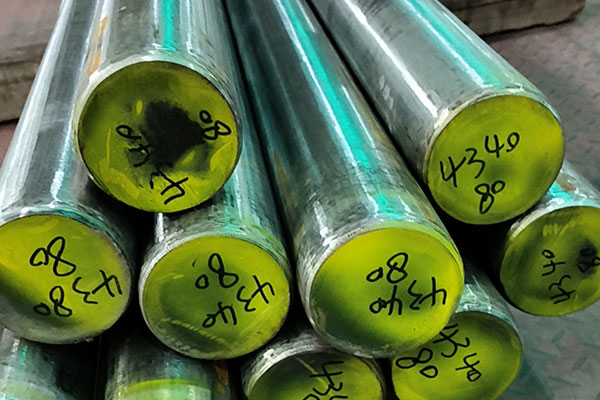

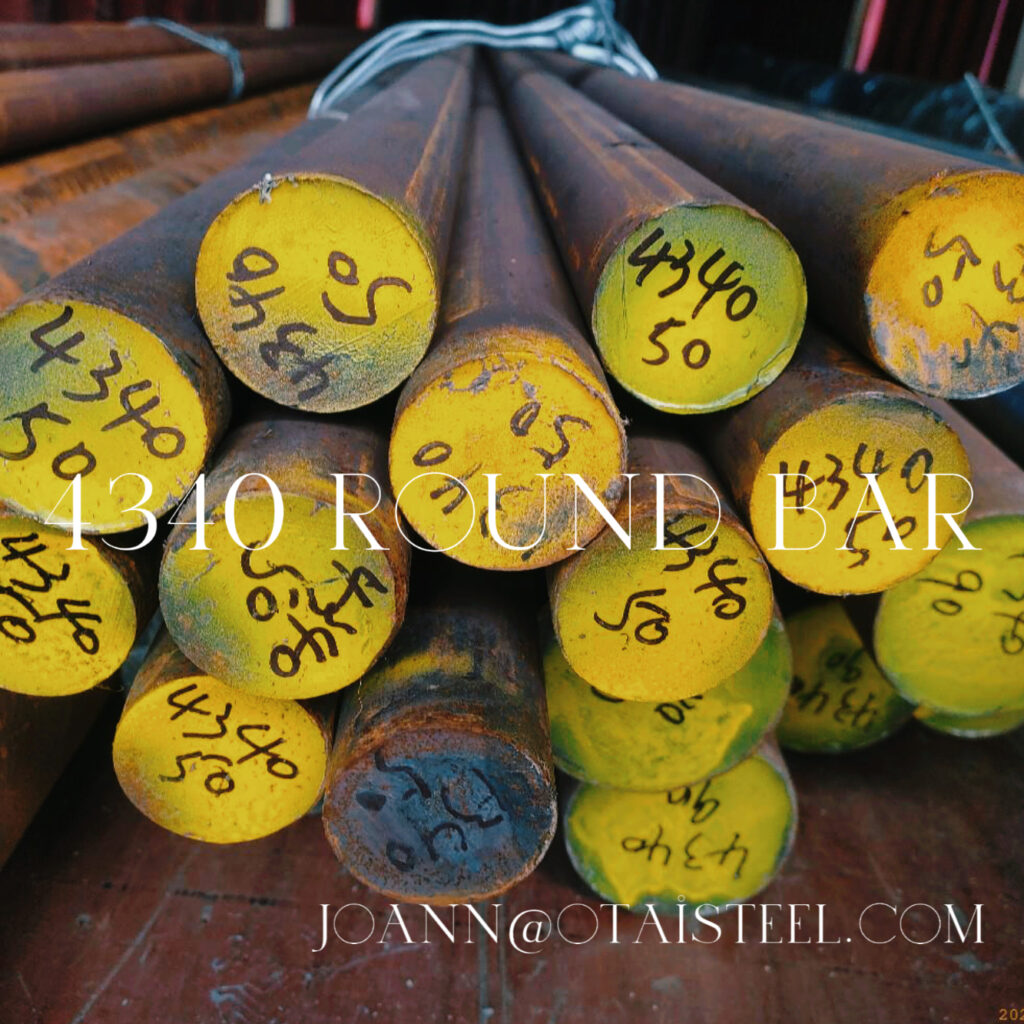

4340 Steel: This alloy contains a higher percentage of nickel and molybdenum compared to 4140 steel. This results in superior toughness and fatigue resistance, making it an excellent choice for applications involving heavy loads and high-stress conditions.

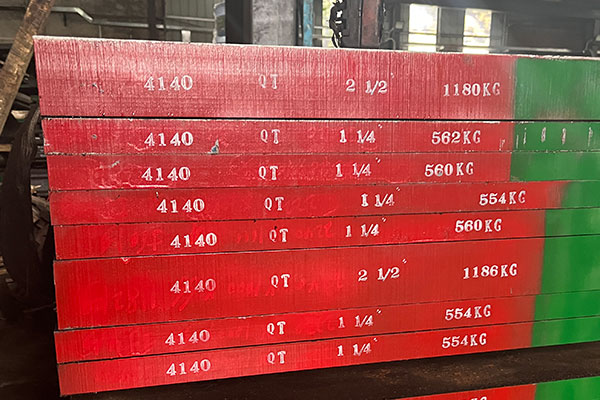

4140 Steel: While still a robust steel, 4140 has a lower concentration of nickel and molybdenum. It is known for its exceptional hardness, making it suitable for applications where wear resistance is crucial.

Applications:

The choice between 4340 and 4140 steel depends largely on the specific requirements of the application:

4340 Steel Applications:

Aerospace components like landing gear and structural parts.

Crankshafts and other components in automotive and racing industries.

Oil and gas drilling equipment due to its high strength and toughness.

4140 Steel Applications:

Gears, shafts, and spindles in machinery and equipment.

Automotive parts such as axles, bolts, and connecting rods.

Firearms components due to its excellent hardness and impact resistance.

Machinability:

4340 : Compared to 4140 steel, 4340 contains a higher composition of nickel and molybdenum. This results in better toughness and fatigue resistance, making it an excellent choice for applications involving heavy loads and high stress conditions.

4140 :4140 is known for its good machinability and can be easily machined using standard machining processes. This makes it the first choice for applications requiring complex shapes and precision.

Heat Treatment:

Both steels respond well to various heat treatment processes, allowing for customization of their mechanical properties. They can be hardened through processes like quenching and tempering to achieve specific levels of hardness and toughness.

Cost Considerations:

In terms of cost, 4140 steel tends to more economical than 4340. This is primarily due to the higher alloy content of 4340, which makes it more expensive to produce.

Conclusion:

In summary, 4340 and 4140 steels are both excellent choices for different applications depending on the specific requirements. 4340 offers superior toughness and fatigue resistance, making it ideal for high-stress applications like aerospace components. On the other hand, 4140 prize its hardness and wear resistance, making it a top choice for gears and automotive parts.

FAQs:

Can 4340 and 4140 steel be welded?

Yes, both steels can weld using conventional welding techniques. However, it’s essential to follow proper welding procedures to maintain the integrity of the material.

Which steel better suit for high temperature applications?

With higher nickel and molybdenum content, 4340 steel has enhanced heat resistance, making it better suited for high-temperature applications.

Are there any restrictions on the size or shape of parts made from these steels?

While both steels use to produce a variety of components, factors such as machinability and heat treatment may affect the feasibility of certain shapes or sizes.

Do 4340 and 4140 steel require special storage or maintenance considerations?

These steels should be stored in a dry environment to prevent corrosion. Additionally, applying an appropriate rust inhibitor can help prolong their lifespan.

Can these steels use interchangeably in certain applications?

In some cases, yes. However, it’s crucial to consider the specific demands of the application and choose the steel that best aligns with those requirements.

Remember, before choosing between 4340 and 4140 steel, it’s essential to evaluate the specific needs of your application to ensure the optimal material selection.

Otai special steel is the largest 4140 stockist in South of China ,if you want to know more information about the 4140 and 4340 , pls feel free contact us.

Joann,E-mail:joann@otaisteel.com ;WhatsApp:+8613128068365

No comments

[…] Steel: We also introduce in last artical . 4140 steel also known as chromoly steel, 4140 contains 0.38%-0.43% carbon along with other […]