A36 and 4140 steel are two distinct types of steel with unique properties and applications. To begin with, understanding their differences is crucial for selecting the right material for specific projects. In this comparison, we’ll delve into the characteristics, applications, and advantages of both A36 and 4140 steel.

Chemical Composition

- A36 Steel:

- Carbon (C): 0.25%

- Manganese (Mn): 1.03%

- Phosphorus (P): 0.04%

- Sulfur (S): 0.05%

- Silicon (Si): 0.4%

- Copper (Cu): 0.2%

- 4140 Steel:

- Carbon (C): 0.38-0.43%

- Manganese (Mn): 0.75-1.00%

- Phosphorus (P): 0.035%

- Sulfur (S): 0.040%

- Silicon (Si): 0.15-0.35%

- Chromium (Cr): 0.80-1.10%

- Molybdenum (Mo): 0.15-0.25%

The Properties of A36 and 4140 Steel

The Properties of A36 and 4140 Steel

- A36 Steel:

- Tensile Strength: 400-550 MPa (58,000-80,000 psi)

- Yield Strength: 250 MPa (36,000 psi)

- Brinell Hardness: 119-162HB

- 4140 Steel:

- Tensile Strength: 655-760 MPa (95,000-110,000 psi)

- Yield Strength: 415 MPa (60,000 psi)

- Brinell Hardness: 197HB

Different Applications of A36 and 4140 Steel

- A36 Steel:

- A36 steel is commonly used in construction, structural applications, and general fabrication due to its versatility and relatively low cost. Additionally, it finds wide employment in bridges, buildings, and various types of machinery.

- 4140 Steel:

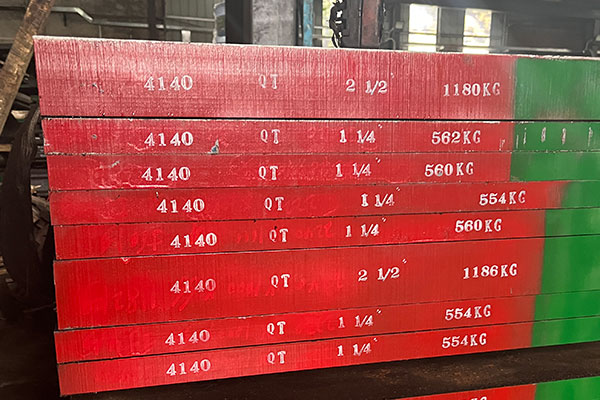

- In contrast, 4140 steel is primarily utilized in high-stress applications such as automotive components, gears, axles, and tooling. Furthermore, it proves suitable for parts subjected to high levels of wear and tear.

Heat Treatment

Heat Treatment

- A36 Steel:

- Not heat-treatable. It undergoes a mild cold-working process to improve its mechanical properties.

- 4140 Steel:

- Can be heat-treated to achieve a range of hardness levels, making it highly adaptable for specific applications.

Weldability

- A36 Steel:

- Easily weldable, making it suitable for a wide range of applications.

- 4140 Steel:

- More challenging to weld due to its higher carbon content. Preheating and careful selection of welding procedures are crucial.

Cost Considerations

- A36 Steel:

- Relatively economical, making it a popular choice for general-purpose applications.

- 4140 Steel:

- Moderately more expensive than A36 due to its alloying elements, but provides superior performance in high-stress environments.

Conclusion

Conclusion

In summary, A36 and 4140 steel cater to different industries and applications. A36 is versatile and widely used in construction, while 4140 excels in high-stress scenarios, thanks to its impressive strength and heat-treatable properties. Choosing between them depends on the specific requirements of the project.

FAQs

- Can A36 steel be heat-treated?

- No, A36 steel is not considered a heat-treatable material.

- What industries commonly use 4140 steel?

- 4140 steel finds applications in automotive, aerospace, and oil and gas industries, among others.

- Is 4140 steel more expensive than A36?

- Yes, 4140 steel tends to be moderately more expensive due to its alloying elements.

- What are the primary advantages of A36 steel?

- A36 steel is known for its versatility, ease of welding, and cost-effectiveness.

- Can 4140 steel be welded?

- Yes, 4140 steel can be welded, but it requires specific procedures and precautions due to its higher carbon content.

A36 and 4140 steel both are stock steel in Otai special steel , if you want to know more details about the application and performance of A36 and 4140 steels , pls feel free contact us.

Contact : Joann /E-mail:joann@otaisteel.com /WhatsApp:+8613128068365

Our main Website:http://www.otaisteel.com