Steel forms the backbone of modern industry, and among its diverse family, one alloy particularly stands out for its exceptional versatility and strength – 4140 steel. In this comprehensive guide, we’ll delve into 4140 steel, exploring how to find a reliable 4140 steel supplier.

What is 4140 Steel?

4140 steel is a low alloy with high tensile strength, toughness, and excellent wear resistance.

Properties of 4140 Steel

High Tensile Strength: One of the most notable characteristics of 4140 steel is its impressive tensile strength, making it suitable for applications under high-stress conditions. It excels in automotive components or structural elements.

Toughness and Impact Resistance: Its composition grants 4140 steel exceptional toughness, allowing it to withstand impacts and dynamic loading conditions. This property makes it a popular choice in manufacturing gears, axles, and other machinery components.

Good Fatigue Strength: Another key advantage of 4140 steel is its resistance to fatigue. This property is crucial for components subjected to cyclic loading, such as aircraft landing gear or automotive suspension parts.

Excellent Wear Resistance: The inclusion of molybdenum in 4140 steel significantly enhances its wear resistance, making it suitable for tooling applications where abrasion is a concern.

Machinability: Despite its high strength, 4140 steel maintains good machinability when treated properly. This allows for precise and efficient manufacturing processes.

Applications of 4140 Steel

Applications of 4140 Steel

Automotive Industry: The automotive industry heavily relies on 4140 steel. It’s used in a range of components including axles, crankshafts, gears, and connecting rods.

Aerospace Components: Due to its excellent strength-to-weight ratio and fatigue resistance, 4140 steel finds applications in aerospace components like landing gear, shafts, and structural elements.

Oil and Gas Industry: The oil and gas sector often employs 4140 steel in the manufacturing of drill collars, subs, and other downhole equipment, thanks to its combination of strength and corrosion resistance.

Tool and Die Making: 4140 steel’s wear resistance and machinability make it a popular choice for tool and die production, where precision and durability are paramount.

Sourcing 4140 Steel: Choosing the Right Supplier

When it comes to procuring 4140 steel, selecting the right supplier is crucial for ensuring quality and reliability. Look for a supplier with the following attributes:

Reputation and Experience: A reputable supplier has a track record of providing high-quality 4140 steel to various industries. Look for reviews, testimonials, and years in business.

Certifications and Standards: Ensure that the supplier adheres to industry standards and holds relevant certifications, such as ISO 9001 for quality management.

Customization Options: A reliable supplier should offer customization options to meet specific requirements, such as different sizes, shapes, or heat treatments.

Timely Delivery and Logistics: A supplier’s ability to meet delivery deadlines and provide efficient logistics support is crucial for keeping projects on schedule.

Technical Support and Expertise: A reputable supplier should have a team of experts . It can provide technical advice and support throughout the procurement process.

Conclusion

In the world of steel alloys, 4140 steel stands tall for its exceptional properties and wide-ranging applications. Its combination of high strength, toughness, and wear resistance make it a go-to material for industries spanning automotive, aerospace, oil and gas, and tool making. When sourcing 4140 steel, it’s imperative to partner with a trusted supplier who can provide the quality and reliability needed for your projects.

FAQs

FAQs

Is 4140 steel suitable for welding applications?

Yes, 4140 steel can be welded, but it requires proper preheat and post-weld heat treatment to prevent cracking.

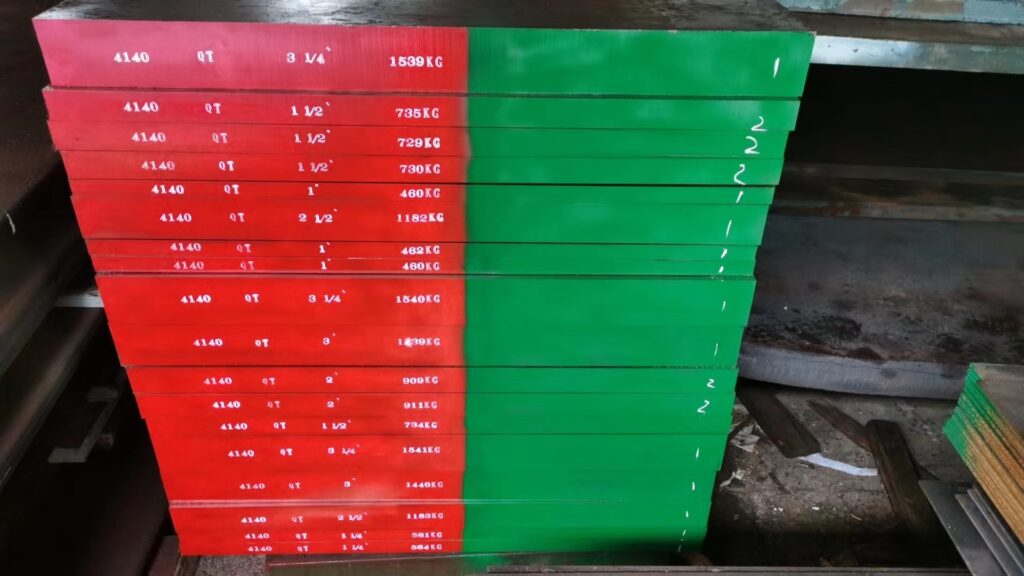

What are the available forms of 4140 steel?

4140 steel is available in various forms, including round bars, flat bars, plates, and seamless tubing.

Can 4140 steel be heat treated for further enhancement of its properties?

Yes, 4140 steel can undergo processes like quenching and tempering to further improve its mechanical properties.

What industries commonly use 4140 steel?

Industries such as automotive, aerospace, oil and gas, and tool and die making frequently utilize 4140 steel for various components.

What are some alternatives to 4140 steel for high-stress applications?

Some alternatives include 4340 steel, 8620 steel, and 6150 steel, which offer similar properties and are often chosen based on specific application requirements.

Dongguan Otai special steel ., Ltd stock more than 300otons of 4140 steel stock . We have the ISO9001-2022 certificate and accept the third party inspecition like SGS. For delivery time , we delivert 15% faster than competitiors.

Welcome to inquiry, Contact : Joann , E-mail:joann@otaisteel.com; WhatsApp:+8613128068365