In modern industry, 32CrMoV12-10 steel belong to alloy steel , which play a crucial role because they have high strength, good heat treatment properties and excellent corrosion resistance. 32CrMoV12-10 also know as 1.7765 which under the DIN standard , it is a high-quality material that works under high load and high temperature conditions. It plays a decisive role in industrial operations.

Chemical composition about 32CrMoV12-10 steel

| C | Si | Mn | S | P | Cr | Mo | Ni | V | |

| 32CrMoV12-10 | 0.30-0.35 | Max 0.35 | Max 0.60 | Max 0.025 | Max 0.01 | 2.80-3.20 | 0.80-1.20 | / | 0.25-0.35 |

32CrMoV12-10 container proper pencent Chromium , it improved its corrosion resistance and extended service life.

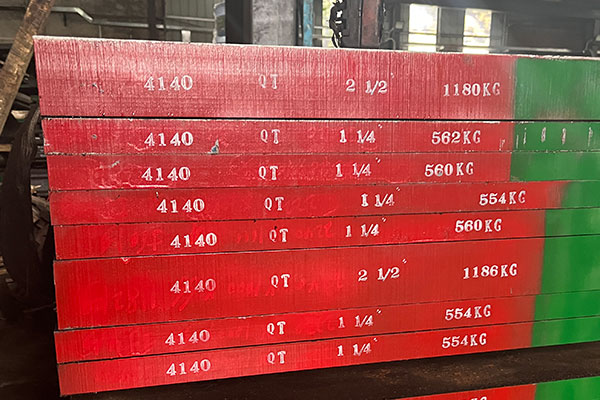

32CrMoV12-10 steel delivery condition

As usual ,32CrMoV12-10 steel delivery as QT condition

Mechanical properties

|

Grade

|

Condition

|

Yield strength min

[MPa]

|

Tensile strength

[MPa]

|

Elongation A

5

[%]

|

Reduction of area Z

min

[%]

|

Hardness[HRC]

|

|

32CrMoV12-10

|

QT

|

Min 800

|

Min 940

|

Min13%

|

70

|

Min26HRC

|

Heat treatment about 32CrMoV12-10

Heat treatment about 32CrMoV12-10

Forging

– Slowly heat 32CrMoV12-10 steel material to 1100-850°C. Due to the relatively high thermal strength of this steel, the initial hammer blow should be light.

Annealing

– Annealing temperature:Heat to approx. 720°C, cool slowly.

– Hardness :Maximum 224 HB

Quenching:

-Quenching temperature: 860-890℃

-Medium: oil, water or air

-Hardness: 53-58 HRC

Tempering:

– Tempering temperature: 540-680℃

– Hardness: ≤45 HRC

– Tempering time: Depends on specific materials and requirements

Application area

32CrMoV12-10 is often used to manufacture equipment and parts that operate under high load and high temperature, such as automobile engine connecting rods, mechanical tool blades, pneumatic tools, molds, and weapon manufacturing, such as gun barrels, etc.

Advantages and features of 32CrMoV12-10

- High strength: 32CrMoV12-10 has excellent tensile strength and yield strength, and is suitable for working environments that bear large loads and pressures.

- Good heat treatment performance: This alloy steel can adjust the hardness and toughness of the material through quenching and tempering processes to adapt to different usage requirements.

- Excellent corrosion resistance: 32CrMoV12-10 adds an appropriate amount of chromium to improve its corrosion resistance and extend its service life.

If you want to know more about the 32CrMoV12-10 or want to get a quotation , please do not hesitate contact us .