4140 and 52100 both are widely used steel , they are often compared and evaluated for their suitability in various applications. In this article, we’ll explore the characteristics, properties, and applications of these two steel types, highlighting their differences and unique features.

4140 and 52100 both are widely used steel , they are often compared and evaluated for their suitability in various applications. In this article, we’ll explore the characteristics, properties, and applications of these two steel types, highlighting their differences and unique features.

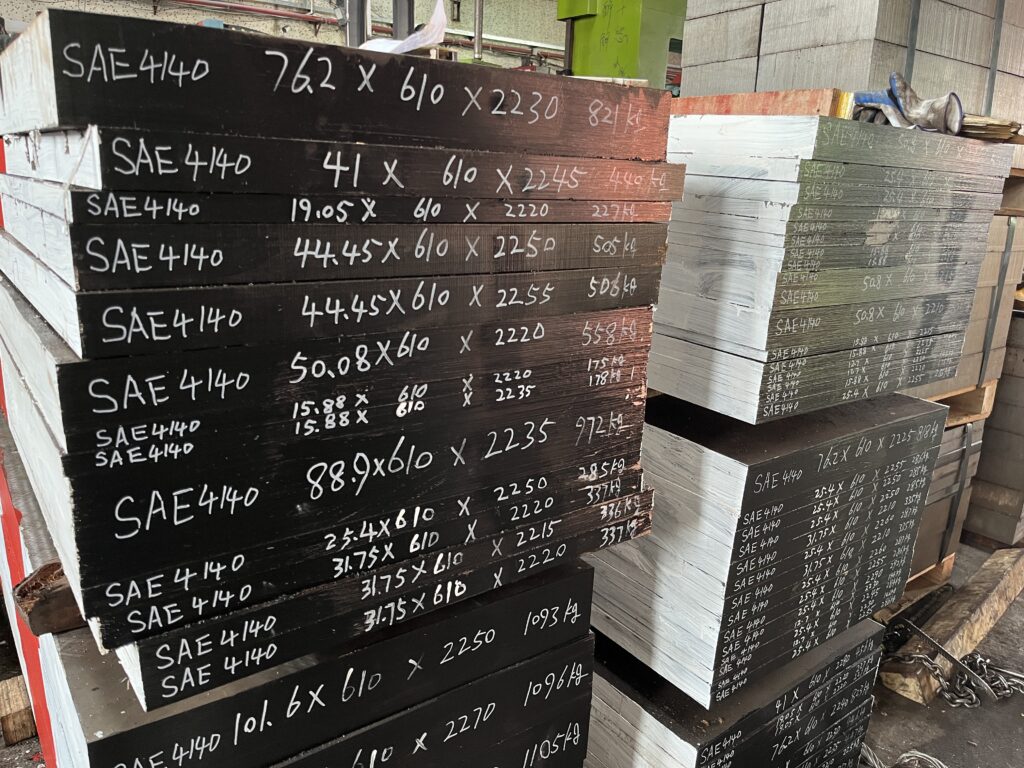

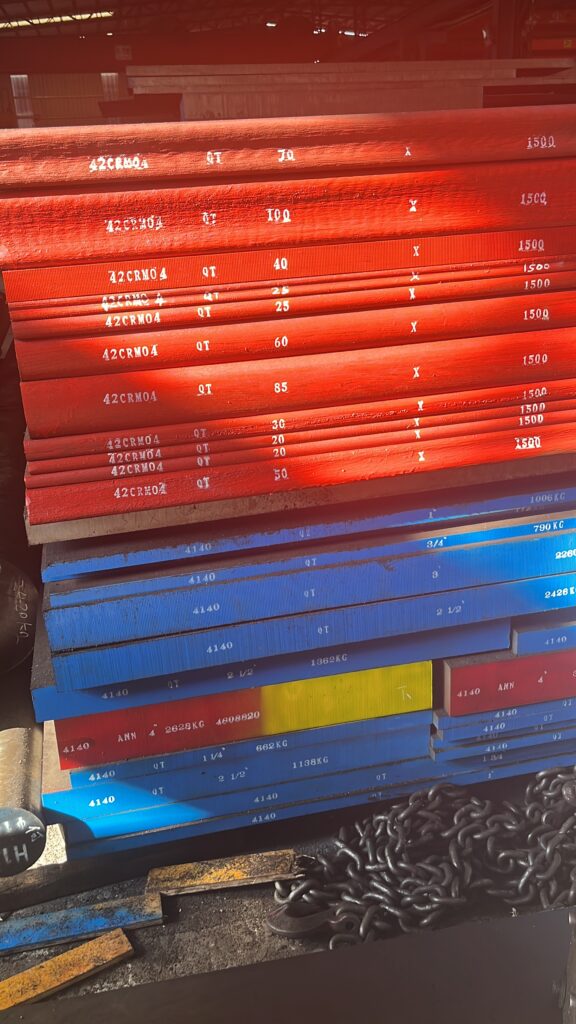

4140 Steel

Composition and Characteristics

4140 steel, also known as AISI 4140 or SAE 4140, is a low alloy steel known for its strength, toughness, and high fatigue resistance.Chemical composition is below :

| C | Si | Mn | S | P | Cr | Mo | Ni | |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | ≤0.035 | 0.80-1.10 | 0.15-0.25 |

Properties

– Tensile Strength: 4140 steel boasts a tensile strength of approximately 655 MPa, making it suitable for applications where high strength is essential.

– Hardness: It can be heat-treated to achieve a hardness ranging from 28 to 32 HRC (Rockwell C scale).

– Weldability: 4140 steel can be welded, although it requires pre- and post-weld heat treatments to maintain its properties.

– Applications: Commonly used in machinery components, axles, connecting rods, and a variety of industrial applications.

52100 Steel

Composition and Characteristics

52100 steel, also known as bearing steel, composition is below:

| Grade | C | Mn | P | S | Si | Ni | Cr | Cu | Mo |

| 52100 | 0.93-1.05 | 0.25-0.45 | 0.025 | 0.015 | 0.15-0.35 | 0.25 | 1.35-1.60 | 0.3 | 0.1 |

Properties

– Tensile Strength: 52100 steel offers a tensile strength of around 680 MPa, slightly higher than 4140 steel.

– Hardness: It can achieve high hardness levels, typically around 60 to 66 HRC, making it ideal for bearing applications.

– Wear Resistance: Due to its composition, 52100 steel excels in applications where resistance to wear and abrasion is crucial.

– Applications: Predominantly used in bearing components, such as ball bearings, roller bearings, and other high-load applications.

Key Differences

Key Differences

1. Composition: The primary difference between these two steels is their composition. While 4140 steel is a low alloy steel with a balanced mixture of elements, 52100 steel contains a higher percentage of chromium for improved wear resistance.

2. Tensile Strength: 52100 steel has a slightly higher tensile strength compared to 4140 steel. This makes 52100 more suitable for applications where extreme strength is required.

3. Hardness: 52100 steel is significantly harder than 4140 steel. The high hardness of 52100 steel makes it ideal for bearing applications, where the material must withstand heavy loads and friction.

4. Weldability: 4140 steel is more weldable than 52100 steel, although it still requires proper pre- and post-weld heat treatments to maintain its properties. In contrast, 52100 steel is less weldable due to its high chromium content.

Conclusion

In summary, both 4140 and 52100 steel have their strengths and applications. 4140 steel offers a good balance of strength and toughness, making it suitable for various machinery components and industrial uses. On the other hand, 52100 steel, with its high hardness and exceptional wear resistance, is the top choice for bearing applications. When selecting between the two, it’s essential to consider the specific requirements of your project and choose the steel that best matches your needs.

4140 and 52100 FAQs

1. Can 4140 steel be used in bearing applications?

4140 steel is not typically used for bearing applications due to its lower hardness and wear resistance. It’s better suited for components that require strength and toughness.

2. What are the advantages of 52100 steel in bearing applications?

52100 steel’s high hardness and excellent wear resistance make it ideal for bearing applications, where it can withstand heavy loads and friction.

3. Is 4140 steel more cost-effective than 52100 steel?

Generally, 4140 steel is more cost-effective than 52100 steel, making it a popular choice for a wide range of industrial applications.

4. Can 4140 and 52100 steel be heat-treated for improved properties?

Yes, both 4140 and 52100 steel can be heat-treated to enhance their properties, including hardness and strength.

5. Are there any corrosion resistance differences between 4140 and 52100 steel?

52100 steel has better corrosion resistance due to its higher chromium content, making it suitable for applications where exposure to moisture or corrosive environments is a concern.

Want to know more about the details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365