This week, I had a customer inquire with us about several mould steel NAK80, S136 and P20. We knew that these steels would be used in plastic molds, and he wanted to compare the prices of these materials. This article analyzes the differences between the above materials and helps customers choose the most suitable material.

Description of mould steel S136,NAK80 and P20:

S136 steel is chromium-nickel-molybdenum-vanadium alloy steel. As a high-quality plastic mold steel, S136 is widely used in injection molds, extrusion molds, blow molds and other fields. This mold steel has excellent corrosion resistance, polishability, wear resistance, and machinability, making it an ideal choice for manufacturing high-quality, high-precision plastic products.

S136 steel is chromium-nickel-molybdenum-vanadium alloy steel. As a high-quality plastic mold steel, S136 is widely used in injection molds, extrusion molds, blow molds and other fields. This mold steel has excellent corrosion resistance, polishability, wear resistance, and machinability, making it an ideal choice for manufacturing high-quality, high-precision plastic products.

NAK80 steel is a kind of pre-hardened plastic mold steel, it is from Japan ,Daido . NAK80 steel generally used for mirror polishing molds, dustproof, TV filter plates, cosmetic boxes, precision wrinkle treatment molds, office automation equipment, auto parts electrical discharge processing molds, etc.

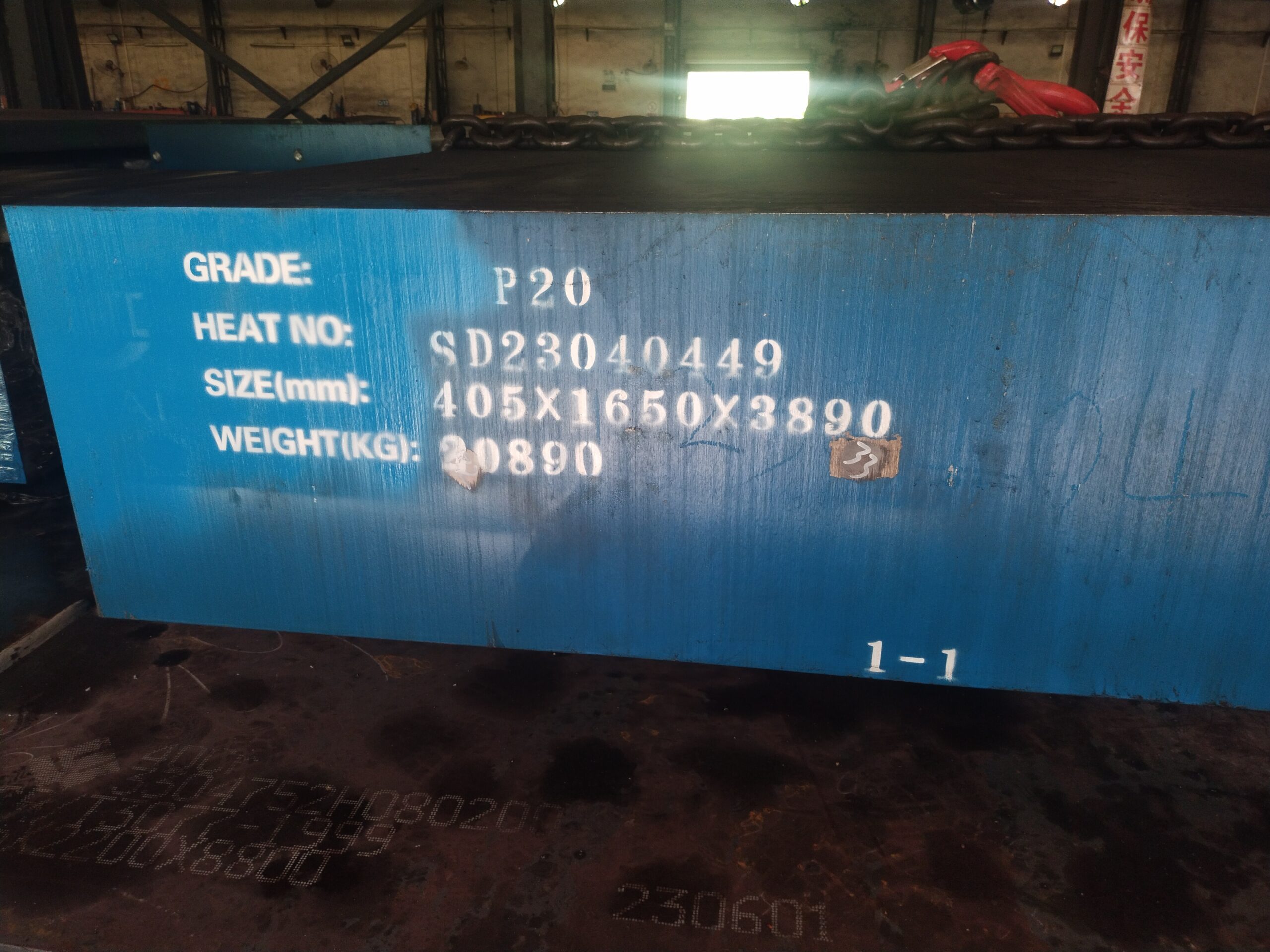

P20 steel is an American standard pre-harden plastic mold steel. Widely used in China, factory hardness HRC30~42, suitable for large and medium-sized precision molds, suitable for long-term production of high-quality plastic molds, and used for large mold bases. This steel has good machinability and can be generally polished.

Chemical composition difference

| Grade | C | Si | Mn | S | P | Cr | ||

| ASSAB | S136 | Max0.38 | Max0.80 | Max0.50 | MAX0.030 | MAX0.030 | Max13.6 |

| Grade | C | Si | Mn | S | P | Cr | Mo | |

| ASTM | P20 | 0.28-0.40 | 0.20-0.80 | 0.60-1.00 | ≤0.030 | ≤0.030 | 1.40-2.00 | 0.30-0.55 |

| Grade | C | Si | Mn | Cr | Mo | Ni | Al | Cu | |

| JIS | NAK80 | 0.15 | 0.30 | 1.50 | 0.30 | 0.30 | 3.00 | 1.00 | 1.00 |

Characteristic between mould steel S136 , NAK80 and P20

S136 mold steel

- Corrosion resistance: It has excellent corrosion resistance and apply in humid environments for a long time without rusting.

- High hardness: It has high hardness and can maintain good hardness and wear resistance at high temperatures.

- Excellent cutting performance: It has good cutting performance and is easy to process and manufacture.

- Good heat treatment performance: It has good heat treatment performance and can obtain the required hardness and strength through heat treatment.

- Excellent wear resistance: It has excellent wear resistance and can maintain good surface finish and dimensional accuracy during long-term use.

NAK80 steel

- High hardness: NAK80 mold steel is pre-hardened steel, and its hardness can reach 37-43HRC before leaving the factory.

- Excellent polishing performance: very suitable for molds with high surface requirements, such as optical devices or injection molded parts

- Ease of processing: NAK80 has very good processing performance, is easy to cut, mill and drill, and can meet the requirements of mold processing.

- Good thermal stability: NAK80 can still maintain stable performance in high-temperature working environments. It has a low thermal expansion coefficient and excellent thermal conductivity, and can effectively resist plastic mold deformation and thermal stress caused by high temperatures.

P20 steel

- Hardness: Factory pre-hardened, hardness 29-33HRC. Uniform hardness, good polishing performance and photo-etching performance, and good processing performance

- It has excellent cutting performance and wear resistance, and can withstand high pressure and impact. Suitable for long term mold use.

- P20 mold steel also has high strength and toughness and can withstand long-term mold work.

- It has good heat resistance and corrosion resistance, making it the first choice material for plastic injection molds.

Application between mould steel S136 , NAK80 and P20

NAK80 Steel application :

Mould steel NAK80 widely used in plastic injection molds, die-casting molds and precision molds also in industries such as auto parts, home appliances, electronic products, and medical devices.

It is suitable for flat panel displays, cameras, audio equipment, transparent covers, films and other shell molds with mirror polishing requirements.

S136 steel application

S 136 is suitable for plastic molds with high corrosion resistance and mirror polish requirements.

Therefore the highly smooth surfaces of S136 steel for the production of optical products, such as cameras, sunglasses, chemical instruments and plastic products;

P20 Steel application

P20 Steel application

- P20 is suitable for plastic molds and mold bases such as TV front casings, telephones, water dispensers, vacuum cleaners, etc.

- Thermoplastic plastic injection molds, extrusion molds.

- Thermoplastic blow molds. Heavy duty mold main components.

- Cold structural parts.

- Commonly used in manufacturing TV casings, washing machines, refrigerator inner casings, buckets, etc.

The difference of price between mould steel S136 , NAK80 and P20

P20 < S136 < NAK80

In conclusion

S136 , NAK80 and P20 are all good material widely used for steel mould.

But there are some application differences.

- If you need a mold with good polishability and relatively high requirements, you can choose NAK80 steel.

- If you want to produce injection molds or extrusion molds with certain corrosion resistance but also have certain surface requirements, you can choose S136 steel.

- If you have a budget Limited, if the surface requirements are not high, you can choose the more cost-effective P20 steel.

Otai special steel stock more than 1500tons for S136 , NAK80 and P20 steel. If you want to get the stock list and the price details , please contact below information:

Name: Joann

Name: Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365